Objective

After this study, people will be able to know-

- Development and establishment status of paper industry in India,

- Distribution and production status of paper industry in India

- Status of Newsprint Industry

- Foreign trade of paper industry in India

- Problems and prospects of paper industry in India.

Introduction

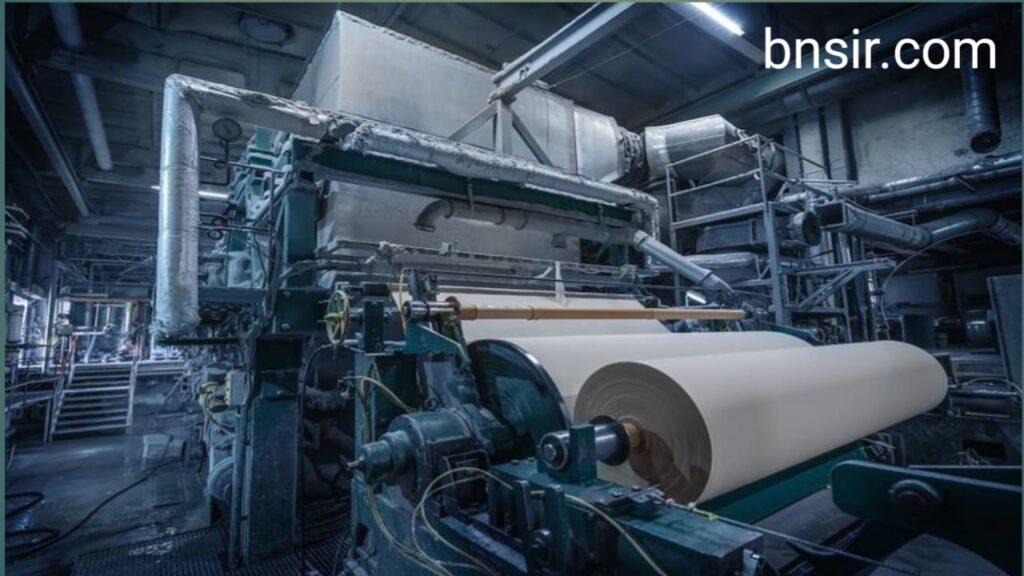

The paper industry is the foundation of modern civilization, it can be called “the road to civilization”. Paper is an indicator of education and civilization. Paper was probably first made in China. Before 1840, paper was made from cotton, cloth, linen and their rags. After 1840, the pulp was used to make paper. The paper made from the pulp is of very good quality.

Development of Paper Industry

The present paper industry in India dates back to the 18th century. The first unsuccessful factory was established at Trakubar in Chennai in 1716 AD but the real development started with the establishment of paper industry in Lucknow in 1879 and Titagarh in 1881.

After this, gradually new factories were established in many parts of the country. It got a lot of encouragement from the government patronage during the First and Second World War. After independence, rapid development of this industry started. At present, there are 56 large paper factories in India, but their number is about 450 by mixing medium and small factories.

Raw Material

Wood pulp, grass, bamboo, rags of cloth, jute etc. many materials are used for making paper. There is a shortage of wood for making wood pulp in our country. This pulp is made from coniferous trees, pine, spruce, hemlock, fir which are lacking in our country. These trees are found in the remote places of the Himalayas. That’s why pulp is used less in our place.

In our country, pulp is prepared from the wood of salai, wattle, eucalyptus, mulberry, balsam. Newsprint is specially made from it. Now sugarcane bagasse for making paper and pulp has come to be used. Still, due to lack of raw material, the paper could not meet its potential. Only 70 percent are able to use it.

Utilization of Raw Materials Presently, the utilization of raw materials in the country is as follows: 8

- Raw material obtained from letters like- bamboo, hard wood, grass etc – 53%

- Raw material obtained from agricultural produce – 23%

- Waste paper – 15%

- Other raw material – 9%

In addition to raw materials, this industry requires many chemical substances, which are as follows – caustic soda, lime resin, chlorine, sulfur, alum, bleaching powder, ammonia sulfate, soda ash, rock salt, etc.

Pattern of Location

This industry is a weight loss industry. Normally Its required 2.38 tons of bamboo is used to make one ton of paper. This is how its raw material is. Keeping in view the condition of the raw material areas, most of the factories of the country are located at such places where the production expenditure is minimum and there other facilities are specially available.

Thus this industry is a raw material based industry. The condition of the raw material has more influence on its establishment than the market.

Distribution

Like the cotton textile industry, the geographical distribution of this industry also presents two different pictures. Earlier this industry was confined to the Hooghly river areas of West Bengal in the initial stage of its development and then later this industry spread to other parts of the country.

The paper industry is a vast industry. More than 70% of the country’s paper is produced in West Bengal, Andhra Pradesh,

It is obtained from Orissa, Maharashtra, Karnataka and Andhra Pradesh.

West Bengal: This state produces almost half of the country’s paper. The reason for this is the availability of the following facilities here.

- Beautiful wood and bamboo are obtained from Sundarbans.

- Chemical substances are obtained from the industrial region of Kolkata.

- Kolkata is a developed metropolis, so market is available nearby.

- Coal is available from Raniganj and Jharia.

- Clean water is available from Damodar and Hooghly rivers.

- Cheap labor becomes available from Bihar.

- Damodar and Murakshi schemes have started supplying hydropower.

- Many urban settlements are being developed.

- Kolkata is a port and trading city

Due to all these favorable conditions, many paper mills are located in the state.

Major centers: Titagarh, Raniganj, Naihati, Kankinara, Triveni, Kolkata, Chandrahati, Badnagar and Shivraphuli.

Andhra Pradesh: The development of paper industry here has started late. It produces 12% of the country’s paper. Bamboo is the main raw material here. Major centers are Sirpur, Rajamahendi, Tirupati.

Orissa: Bamboo is abundantly available in this state, it produces about 11% of the country’s paper. The main center is Prajrajnagar, Raigad.

Maharashtra: It also produces about 11% of the country’s paper. Here bamboo, sugarcane bagasse, The rag or imported pulp is used for making paper. Two news papers have been found in major centers Pune, Mumbai, Colaba, Kalyan, Vadavali, Ballarpur and Sangli.

Gujarat: It produces 03% of the country’s paper. Major centers Vadodara, Willomoria, Rajkot, Surat, Udvada and Gondal.

Karnataka: This state has the facilities of bamboo, water power market etc. in major centers Bhadravati, Dandli, Bangalore, Belgola and Ramnagar are included.

Madhya Pradesh: Sawai grass is accessible here due to the large expanse of forests. Salai Eucalyptus wood is also available here. It produces 9% of the country’s paper. Major centers: Indore, Bhopal, Sehore, Shahdol are prepared. Newsprint factory is located in Nepanagar.

Uttar Pradesh: The paper industry is developed here due to the availability of facilities from nearby areas. Major centres: Saharanpur, Lucknow, Meerut, Naini. Bihar: It produces about 4% of the country’s paper. Major centers are Dalmianagar, Japla, Sindri and Samastipur.

Tamil Nadu: It produces 5% of the country’s paper. The bamboo here is considered more suitable for making pulp. Major centres: Pallipalayam, Charan, Mahadevi, Chennai, Mater, Coimbatore.

Haryana: The development of paper industry is in progress here. Major centers include Faridabad Yamunanagar, Chandigarh.

Kerala: The local geographical conditions are favorable for the establishment of paper industry here. Apart from this, there are many small centres, which are limited. Major centers are Punnalur, Kozhikode and Rayanapuram.

The local geographical conditions are favorable for the establishment of paper industry here.

Apart from this, there are many small centres, which are limited.

Production

India ranks 20th in terms of paper production in the world. The persons engaged in this industry are approx 1.5 million

Writing and printing paper accounts for 53% of the current production, sacking paper 22%, paperboard 16%, newsprint 6%, specialty paper 4%. As the production of paper is increasing in the country, the demand is also increasing more than that.

That’s why tireless efforts are being made by government and private sectors to increase production. Hindustan Paper Corporation Limited was established in 1970 with the objective of setting up establishments related to paper and paper pulp production. This corporation is currently working towards setting up these factories.

Present Status

At present there are about 515 paper and cardboard mills in the country. (including newsprint mills), with an annual total production capacity of about 6.2 million tonnes. Presently this industry is being consumed only about 62% of the installed capacity. During the year 2003-04, 36.89 lakh tonnes of paper and cardboard were produced in the country. To give life to the paper industry, the government has completely delicensed the paper industry from July 17, 1997. India’s estimated per capita paper consumption is 4 kg which is the lowest in the world.

News Paper Industry

National News Print and Paper Mills, known as Nepa Limited, till 1981, produced newspapers in the country.

It was the only paper making mill. At present there are 70 newsprint mills in the country with an installed capacity of about 12.79 lakh tonnes. The production of newsprint during the year 2003-04 was 6.88 lakh tonnes.

To increase the availability and production of newsprint, excise duty has been removed. Import duty on wood pulp has also been removed. Due to the increasing demand of newsprint in the country, it also has to be imported in India. The import of newsprint has been decontrolled since May 1995 and at present, after the abolition of this control, paper is now being imported under an open general license.

International Trade

Due to increasing literacy, the use of paper is also increasing day by day in India. Till now India is not able to meet its increasing demand with domestic production. In the matter of newsprint, India is 80 percent dependent on foreign countries. To meet its requirement, India has to import paper from countries like Canada, Norway, Sweden, Japan and Holland etc. The import volume is increasing every year. In 1951 the import of normal paper was negligible, but in 1996 about Rs 1250 crores were imported.

It is clear from the rapid increase in literacy, industrial consumption and administrative consumption in India that if there is no increase in internal production, there is a possibility of a huge increase in India’s imports. The Government of India is determined to reduce the import of paper by increasing domestic production. For this paper factories are being established in new areas and the capacity of old mills is being expanded.

Problems and Possibilities

There are several important problems facing the Indian paper industry. Its biggest problem is the following:

- The cost of production is high in India.

- It was an industry which got tariff protection in 1925, this protection was till 1995. For the first time in 1995, the government almost scrapped the conservation policy. Import tax has been exempted by 65%. With this, foreign papers entered the Indian market and became successful in the competition. No protest policy was made for this.

- The quality of raw material in India is not good.

- Most of the factories in India have become sick or are on the verge of closure.

- The factories which are working are not able to utilize their full capacity.

- Paper industry is a polluting industry. Despite these problems, the future of this industry is bright.

Despite these problems, the future of this industry is bright. The reasons for this are as follows:

(i) Here the raw material is diversified, which is possible with good technological development.

(ii) There is a lot of waste in the textile industry in India. Handicraft paper industry can be developed in India from this waste. This industry does not require complex technology. Asia’s largest handicraft paper industry in India is in Pondicherry. Here the invitation card is made.

(iii) India’s recycled paper does not increase pollution.

(iv) There is scope for employment in this industry.

(v) It is an eco-friendly industry.

(vi) Paper packing is being preferred over plastic packing.

Therefore, due to all these facts, despite the problems, the future of paper industry is bright. There is immense potential for its development in India. But at the present time it is necessary that this industry should be given tariff protection. Loans should be made available for their development.

This industry is based on rural raw material, so its development needs to be developed as a small scale industry under rural co-operatives. In fact, there is a need to develop this industry as a program for poverty alleviation and rural development.

Conclusion

It is clear from the above facts that the paper industry is one of education and civilization. This is the weight hall industry. Therefore, to avoid the variation of transportation cost, the raw material is supplied to the industry at the source itself. Establishment will be better from economic point of view.

The paper industry in India is mainly located at those places, where there is sufficient facility of raw material. The Government of India is also active for the development of this industry to meet the growing demand. Factories are being established in new areas and the capacity of old mills is being expanded.

Paper Industry | Overview learn from YouTube Vedio 🎬