HISTORY

BEER: The nature of fermentation was probably revealed to our ancestors by pure accident. Someone left probably half chewed barley in closed dish, still moist, ate the left over few days later and found himself delightful after having it. As civilization advanced, the preparation of such beverages too advanced.

China

In China Confucius and Mencius cautioned people against excessive use of wines and spirits. (288 BC-478 BC). The art of distilling beverages started sometimes in 11 century. The Chinese beer today is called Tarasun is made of barley and wheat.

India

The knowledge regarding drinking in India has been procured from an Indian sacred book called Rig Veda. The drink Soma is believed to be prepared from a juice of a creeper (Asclepias) and another drink called Sura was made from Indian Grass called panicum with water, honey, curd and melted butter and barley. These drinks were offered to gods and priests.

Persia

The Soma of Hindus was their Homa and Sura was known as Hura.

Egypt

The myth that Osiris and Isis were inventors of the beer is based upon the religious view of the nature at that time personifying the physical forces useful or harmful to mankind representing them as Gods.

Osiris – represents “king of life”

Isis – queenly spouse

For the legend of beer this religious and poetic background represents worship of both as the inventors of the amber juice of barley. The art of brewing was of very ancient origin, even in Egypt.

Good beer like good bread requires choice ingredients and a master craftsman. It can be made of pure barley, malt or with cheaper substitute such as corn, rice or even corn grits. The conversion of starchy grains into fermentable sugars can be speeded up by adding sugar or even various enzymes. Fine varieties of hops may be added, or cheap hop oils substituted.

A brewer may have water available which is just right for his needs-hard water for British Pale Ales and Bitters, soft water for lagers and stouts or he may add some chemical salts to condition the water. Storage and ageing are important as are storage vessels. Experienced drinkers can taste the difference between beer stored in wooden barrels and that stored in aluminum.

What is taste?

Taste as registered in the taste buds of the mouth and throat, divides itself into sweet, sour, salty and bitter. The flavour of a substance is a combination of impressions received when that substance is taken into mouth, (aroma-burnt, fragrant, pungent, sharp and acidic).

Beer drinkers are quick to detect and very sensitive to negative flavour characteristics such as metallic, bitter or rancid ones.

BASIC MATERIALS REQUIRED FOR BEER MAKING

Malt

High quality barley is the most desirable grain for brewing. There is an ancient saying of Brewhouse in Munich “Malt is the soul of the Beer”. High protein content is not desirable in brewing. High protein means high nitrogen and in turn less amount of carbohydrates. Since ample starch is necessary for conversion to malt, a high protein barley makes for difficult malting and retards the conversion of starch into sugar. On the other hand nitrogen does speed up fermentation once the yeast has been added and produces an active foamy brew.

Two main types of barleys are used for brewing – two row barley and six row barley. Row here refers to rows of fertile flowers. Two row barley is preferable as it has low protein content. Barley which should be selected should have a thin hull, soft grain and rich endosperm. This indicates less nitrogen content and less problem for malting.

Grain should be even in size, wrinkled hulls and be dry and sweet. The largest producer of brewers barley in Europe are France, Britain and Denmark. Considerable quantities are also cultivated in Germany, Czechoslovakia, Poland, Holland, Austria and Spain.

Malt Extracts

These are adjuncts, much cheaper than pure barley. These are laboratory products derived from barley, home brews are made with such extracts but superior beers are never enriched with them. A combination of malt extract and malted barley is a good compromise. These adjuncts are added to increase the volume of the product and decrease the price. Some brewers add up to 30% but some countries maintain a standard and add no adjuncts as in Germany, Luxemburg and Switzerland.

Hops (Humulus Lupulus)

In ancient times hops have been valued for their medicinal properties. Appreciation of flavours they impart to beer is more of recent origin. In ancient times it was used to preserve it. Today Ales and light lagers in United States are made with small quantity of these blossoms. Many other herbs preferred for flavouring beer in ancient times were Balsam, Broom, Centuary, Dandelion, Hay, Mint, Tansy, Wormwood etc. Today the bitter flavour and characteristics beer aroma come from hops. The tranquilizing properties of beer are not from its alcohol content only but from Lupulin a sedative present in grandular hair of hop cones.

The functions of hops are as follows:

a) Flavoring

b) Clarification and preservation-more clarified is the beer, longer is the shelf life.

c) Imparts bitter taste.

d) Acts as an antiseptic, prevents it from bacterial attack

Some varieties of hops which are used:

- Buillon-(U.S.A.): American grown hop is noted for its marked bitterness particularly favoured by brewers of stouts.

- Hallertau (Germany): Bavarian hop used for light beers like lager.

- Fuggle (U.K.): Favourite of British Brewers particularly useful for brown ales.

- Golding (U.K.): Used in light ales.

- Saaz (Czechoslovakia)

Spent hops form a natural filter and settle at the bottom and the liquid can be filtered easily. Spent hops also form a good fertilizer.

Nowadays some breweries use hop powder or hop extract which are readymade and available as proprietary products. Some brewers feel use of these affect the final taste of beer while some say hop extract enhances the taste of beer as undesirable hop oils get evaporated in the process.

Water

The nature of particular water is determined by the salts dissolved in it, this in turn influences the character of the beer. Water with high calciumi content is hard and with low content is soft. The salt content of the water depends upon the soil through which rain seeps before collecting at source. Today the majority of world breweries modify natural water to conform to brewer’s standard.

Some companies abroad those which are using water in its natural form advertise their beer just on quality of their water e.g.

a) Burton-on-Trent’ in U.K. is famous for its natural waterfall. The Burton beer have a high percentage of gypsum (calcium sulphate) which aids clarification and separation of unwanted husk.

b) Olympia – A district in Washington. The beer is made with ‘Tum Water Falls’ recognized throughout the world as one of the best.

Yeast

Yeast is a living cellular organism that feeds on nitrogenous and other substances and reproduces itself, at the same time altering the nature of the substances in which it is working. The enzymes in yeast attack the sugar in the wort and break them into CO₂ and alcohol.

Beer Additives

Beer additives are synthetic products that may or may not be added in it to expedite a number of functions such as:

a) conversion of starch to sugar.

b) adjust the final colour of the product.

c) to prevent the cloudiness.

d) to stabilize the head or collar of the beer.

e) to prolong the shelf life of the beer.

These products may change the taste of natural beer. A few examples are

(i) Gum Arabic – helps to stabilize the head.

(ii) Hydroxy Benzoate – acts as a preservative.

(iii) EDTA – Ethelene Diamine Tetra Acetate-prevents gushing out of the beer.

(iv) Ascorbic Acid – acts as antioxidant.

Nutritive Value of Beer

Protein -1.6-1.7 g

Fat – 0.0 gm

Carbohydrates – 15.9 g

Water – 92%

Ethyl alcohol – 3.8%, variable

Solid and Extracts – 4.2%

Composition of Beer (by weight)

Water – 88-91%

Alcohol – 3.5-4%

Carbohydrates – 4.5%

Proteins – 0.2-0.4%

CO₂ – 0.4-0.45%

Mineral Salts – 0.02%

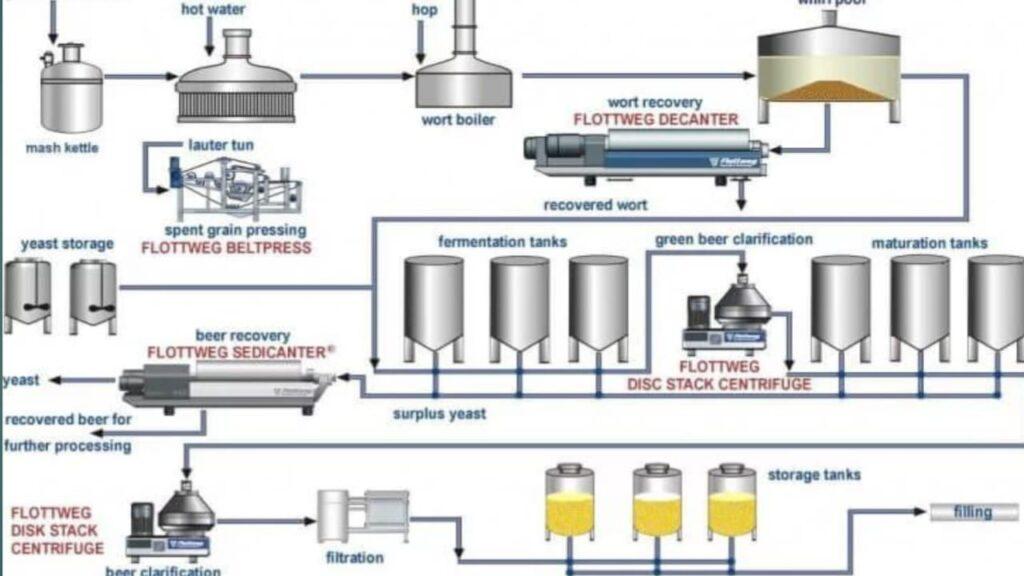

MANUFACTURING PROCESS OF BEER

Brewing is fundamentally a biochemical and biological process. The art and science of brewing is in using and controlling the process to convert natural food to a pure pleasing beverage.

1. Malt: The ripened barley is spread on the malting floor (the kiln floor) on the directions of brew master. After desired germination and treatment on the kiln floor, the barley is allowed to have the requisite colour. The malted barley is put in a mill and ground. This is called GRIST.

2. Mashing: The mashing takes place in a large round tank called Mash Mixer or Mash Tank and requires careful temperature control. In mashing process malt enzymes break down starch to sugar and complex proteins of malt to simple nitrogen compounds. The mash mixer may be made up of copper or stainless steel. Heating coils are attached to heat the liquid with proper control device. Sometimes depending upon type of beer to be made malt is supplemented by starch from other cereals such as corn, wheat or rice.

3. Lautering: When mashing is over the mash is tranferred to draining or lautering vessel, cylindrical in shape with a slotted false bottom 2 inches to 3 inches above the true bottom. The liquid extract runs through false bottom and is run off to brew kettle. Water is sprayed through grains to get as much extract as possible. The left over solid particles are used as a cattle feed.

4. Boiling and Hopping: The liquid in the brew kettle is called wort. The brew kettle can hold 15000-20000 gallons and is made up of shiny copper or stainless steel. It is fitted with coils or jacketed bottom for steam heating and is designed to boil the wort under controlled conditions. During boiling hops are added which impart flavour, aroma and bitterness to the brew. Boiling helps the wort to concentrate to certain specific gravity and sterilize it.

5. Hop Separation and Cooling: The wort is passed through hop Jack or separator to remove both the hops and precipitated protein (or Trub). The wort is cooled in a plate cooler where the temperature drops from 50°F in few seconds.

6. Fermentation: The wort is now moved to the fermenting vessels.

Top Fermentation: In this type of fermentation a volatile reaction takes place at a high temperature and due to production of CO₂ the yeast cells are pushed on the top. Saccharomycetes Cerevisie is usually used for top fermentation.

Bottom Fermentation: In this form of fermentation yeast settles down at the bottom of the fermenting vat as the reaction takes place at lower temperature and production of CO₂ is slower. The yeast used in this is Saccharomycetes Carlsbergenesis.

Top fermentation method is used for brewing stout and ale while bottom fermentation method is used for lager. Top fermentation requires a temperature of about 50°F-70°F and takes about 5-6 days for fermentation. Bottom fermentation requires a temperature of 37°-49°F and takes about 8-11 days for fermentation.

7. Carbonation: CO₂ is injected into the beer. However Germans, Luxumbergians and a Swiss use a method called Krausering meaning to foam or froth. During krausering which takes place after fermentation we add again yeast before or during lagering. The CO₂ is produced in the beer in closed container and the alcohol content is balanced accordingly. Yeast is added as conjunction with wort. Beer additives are added before or after fermenting depending on their function.

8. The cellars: The beer now passes through a period of maturing. It is placed in a cold storage at a temperature of 32°F from one to three weeks. It is filtered and cooled again at 32°F and moved to the chilling storage. After 10-14 days it is polished (clarified) by filtration and transferred to tanks for bottling.

9. Packaging: Bottling, canning, casking /kegs are the most accepted ways of packaging it. Beer should not be stored in wooden barrels because it leaves a woody flavour therefore barrels are lined with aluminum. Wood can withstand pressure of 45 pounds per square inch.

The bottles are inspected both electronically and visually. A crowning machine integrated with the filler, places caps on the bottles. The filled bottles then pass through a tunnel pasteurizer often 75 feet from end to end and able to hold 15,000 bottles where the temperature of beer is raised to 140°F for 10 mins. then cooled to room temperature. Emerging from the pasteurizer the bottles are reinspected, labeled, automatically placed in boxes. Pasteurization adds to shelf life.

SOME ADDITIONAL BREWING DETAILS

Priming

Beer that has been brewed correctly and permitted to age adequately should be perfectly palatable when it is packaged. Brewers who wish to give their beer “zing” of additional CO₂ and want sweeter brew add a solution of invert sugar (lactose) or caramel at racking stage. Priming encourages additional fermentation by leftover yeast and add on more CO₂ and sweeter taste e.g. sweeter lactose in Britain is used for London Stouts. Caramel for drier pale ales and bitters.

Fining

This is done to clarify the beer and remove cloudiness from the beer. Particles rich in vitamins and proteins have tendency to coagulate if not removed, when beer is refrigerated. For fining.

a) Some use asbestos, cellulose or silica

b) Some brewers centrifuge their beer.

c) Some use enzymes like Papain to digest proteinous substances.

d) Some use ising glass which is commonly used, a pure form of gelatine from the swimming bladder of cod. Ising glass solution is made by adding sulphuric acid into it.

Pasteurization

Holding bottles at a temperature of 140°F for 10-15 mins to kill the bacteria and immediately cooling down the same, Draught beer is unpasteurized, unfiltered and fresh. Coor is another U.S beer which is unpasteurized in cans or bottles. Pasteurized beer has three months shelf-life while unpasteurized beer can last for a week under refrigerated conditions.

TYPES OF BEER

Lager

This is the most popular type of beer in U.S.A.and India. It is a amber light beer which has been stored or stocked. The name comes from German verb lagern which means to store. It refers to earlier times when German monks stored it in cool mountain caves during hot summer months.

Lagers are stored or aged up to three months. Alcoholic content of lager is 3.2 to 4%. Lager is produced by bottom fermentation method.

All Indian and American beers are lagered. It is bright, clear light bodied beer which is effervescent.

Light lager

This is pale golden in colour, light-bodied, strongly carbonated and has a soft, dry taste. Lagers are all filtered during brewing which allows them to be refrigerated without any risk of cloudiness, namely:

COOR (U.S.A.)

OLYMPIA (U.S.A.)

RAINIER (U.S.A.)

BUDWEISER (U.S.A. and India)

PIELS (U.S.A. and Czechoslovkia)

GOLDEN EAGLE (India)

BECK’S (Germany)

GENESSE (U.S.A.)

HEINEKEN (Holland)

HARP LAGER (Ireland)

LABATT’S PILSNER (Canada)

CARTA BLANCA (Mexico)

KIRIN (Japan)

CARLSBERG (Denmark)

WURZBERGER (Germany)

PILSNER URQUELL (Czechoslovakia)

LONDON PILSNER (India)

MICHELOB (U.S.A.)

SCHLITZ (U.S.A.)

MILLER (U.S.A.)

RHEINGOLD (U.S.A.)

LÖWEN BRÄU (Germany and India)

SAN MIGUEL (Philippines)

RINGNES (Norway)

FOSTER’S (Australia and India)

Dark Lager

They are brewed by the same technique as light lager but are made dark in colour by addition of dark roasted barley. Imitation dark lagers are made with caramel or roasted barley malt extract. Dark lagers are creamy, more aromatic, sweeter than light lagers. e.g. are

CARLSBERG DARK LAGER (Denmark)

SAN MIGUEL DARK (Philippines)

LÖWENBRÄU DARK SPECIAL (Germany)

Ales

Ales are brewed from the same basic ingredients as lager i.e. barley malt, hops, yeast, water and a smaller amount of adjuncts like rice flakes and corn.

Ales are more aromatic and have pronounced flavour, alcoholic content ranging from 4 to 5%

Ale is most popular beer of Britain. e.g.

BALLANTINE (U.S.A.)

BASS PALE ALE (U.K.)

PABST OLD TANKARD (U.S.A.)

BASS NO. 1 BARLEY WINE (U.K.)

BARCLAY’S WINTER BREW (U.K.)

KING OF ALES (U.K.)

BENSKIN COLNE SPRING (U.K.)

Types of Ales

a) Stout

In addition to ale ingredients, roasted barley is used. These are dark in colour, heavier and bitter than porter.

b) Porter

Light variety of ales. They have lower alcoholic content than the stout. It was very popular with porters of London Metro e.g. GUINNESS (IRELAND)

THE RUSSIAN IMPERIAL STOUT

Ginger Beer

A frothy slightly alcoholic drink, widely consumed in Britain, obtained by fermenting a mixture of sugar, ginger and cream of tartar in water. Its better spicy taste is popular in Britain, where ginger is also used in gingerale (aerated water to which colouring and ginger essence is added).

Dry beer

Dry beers are a result of special mashing process which produces a higher proportion of fermentable to non-fermentable sugar. This results in almost all sugars being converted to alcohol. Dry beers were first developed and marketed in Japan e.g. Power’s Premium Dry (Australia)

Cold filtered beer

Cold filtered beer is kept at sub-zero temperatures throughout its making. It goes through a special filtration process which removes all beer spoilage organisms and yeast cells. No heat pasteurization is necessary. The result is a crisp, fresh state e.g. Carlton cold filtered bitter (the coldie)-Pioneer in Australia in 1993.

lce beer

The filtration process in it involves chilling the beer to very low temperature so that ice crystals form in it, crystals are then removed, result is very smooth beer, Hahn Ice-first Australian ice beer.

Wheat beer

Beer is usually made from barley, but can be made from other grains e.g. wheat. The example of wheat beer is Matilda Bayredback. Wheat beer originated in Germany where it is called Weizen.

Bock beer

It is only manufactured in Bavaria district of Germany and in a town called Einbeck. This is a very famous brewing town. It is brewed during winter for spring market. It is heavy, dark lager beer, full sweet, hoppy in character. Its dark colour is obtained through high coloured malts.

Maibock beer is made till late in winter and is for actually summer market. It does notproduce much head. It is produced in Belgium and U.S.

Alcoholic % of Beer

Indian – 5-8%

Foreign – 5% (less than 5%)

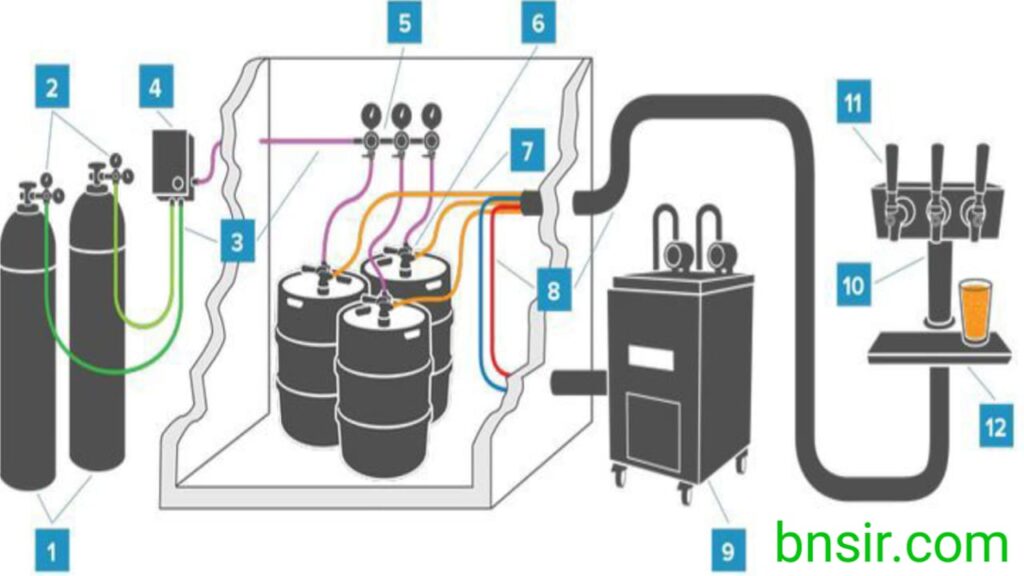

Draught beer

Draught or in USA draft beer is any kind of beer which is drawn from keg (cylinder) as opposed to bottled or canned beer. The beer trade knows it as bulk beer. The brewing process is same as bottled beer, but the level of carbonation is lower than bottled or canned beer. It is less fizzy.

The Beer-dispensing system

A modern hotel bulk beer-dispensing system uses gas, usually carbon dioxide, to propel the beer from a pressurized keg (also called a cask) in the cellar to the bar, and to maintain the carbonization (sparkle) in the beer and give it a good ‘head’ or layer of thick white froth on top when it is served. These are the principal parts of the system:

- Gas cylinder

- Gas plant (pressure reduction, control gauges etc.

- Keg/cask (often a ‘bank’ of several connected kegs)

- Extractor or coupler (to connect the keg to the beer line)

- Beer line

- Cooler

- Tap (or gun).

Not all systems are exactly the same. Different breweries use different systems, and changes are made from time to time to improve them.

Brand Names of Indian Beer

Asia-72, Bombay Pilsner, Bullet, Canon 1000, Canon 10000, Canon 5000, Canon 9000, Club 2000, Club 4000, Dansbeng, Golden Eagle, Guru, Hayward 2000, Hayward 5000, Haywards 1000, Haywards 3000, Kalyani Black Label, Kalyani Black label Premium, Khajuraho, King Fisher, Knockout, London Diet, London Pilsner, Players, President, Punch, Rosy Pelican, Royal challenge Premium, Sun-lager, Swan, Thunderbolt, Vazir.

SOME FAMOUS BEERS OF THE WORLD

Australia

Foster’s lager, Flag Ale, Cooper’s Ale, Victoria Bitter, Melbourne Bitter, Abbott’s Lager, Crown Lager, Carlton Draught Ale, Toohey’s Export Pilsner, Stag Lager, Old Draught, Miller lager, Miller Stout, Oatmeal Stout, Castle Maine, Cascade lager

Austria

Gold Fass! (lager), Gosser Stifts Puntigan

Argentina

Schneider, Rio Sagundo

Belgium – Jupiter (lager)

Brazil – Brahma

Canada

Molson Ale, Molson Lager, Golden Ale, Ten Penny Ale, Alpine lager, London Stout, Uncle Ben

China – Yuchuan Beer, Tsing Tao Beer

Czechoslovakia – Pilsner Urquell

Ireland – Guinness Extra Stout, Draught Guinness

Denmark – Carlsberg Beer, Carlsberg Special Dark Lager, Ceres Red Eric Tuborg

Italy – Peroni Lager

Japan – Kirin Lager, Asahi Lager Beer

England – Bass Ale, Russian Imperial Stout, Double Diamond, Skol, White Bread, Pale Ale, Mackerson Stout

Scotland – Tennent’s Lager, Mac Ewan’s Ale

Germany – Beck’s Beer, Dortmunder Hansa, Löwenbräu, Heineken, Hofbrau

Holland – Heineken Lager Beer, Amstel, Special Dark Beer

Mexico – Carta Blanca, Bohemia Ale Corona

New Zealand – Zealandia, Steinlager

Philippines – San Miguel

U.S.A. – Coors, Genesse Lager Beer, Genesse Cream Ale, Olympia

THE ART OF STORAGE AND SERVING OF BEER

Storage

If it is kept too long in bottles, casks or cans, it gradually loses its subtle flavour. Carefully stored beer in an even temperature in total darkness, there would be great chance of beer retaining its full brewery cellar freshness. Beer should be stored upright. It is lifeless after 3-6 months on the shelf. Draught beer has shelf life of 2 weeks and in tropical countries may be 3 days.

Service

The serving of it is also an art. When pouring beer, it is best to run it along the side of the glass. Hold the glass at an angle, pour a little, then stop to allow first froth to settle, then fill the glass, so that the frothy head stands little above the rim of the glass. One and a half to two inches is an ideal height of the froth. If it is too cold then there will be weak froth, if too warm then there will be too much froth.

The froth bubbles contain carbonic acid gas. The layer of froth will only rebuild if there is enough carbonic acid gas being released continuously. The bubble builders which are present in it are albuminoids and peptones. A high alcohol content results in less froth, while high hop content gives it a good head. Old beer has better froth than young one because of tightly clinging protein molecules.

An ideal temperature for service of it is 8-10°C (40°F-50°F) Lager Beer is served at the temperature of approx 45°F. Ales are served at a temperature of 50°F.

It goes well with sharp tasting sauces, spicy food like Indian food, and creamy substances.

IDEAL STORAGE TEMPERATURE FOR BEER

(1) For bottled, canned or pasteurized beer the approximate temperature is below 70°F in a darker room.

(2) Draught/unpasteurized beer should be kept at a temperature of 26-38°F in a colder place.

Glassware

It can be served in mugs, beer glass, schoqner or a tankard. The traditional Swiss or German way of serving is in stoneware mug with or without a lid, has a neutral taste and smell.

share to help